Simulations have long been a cornerstone of various industries, from engineering and product design to urban planning and flight training. However, traditional simulations often rely on static models and assumptions, limiting their accuracy in reflecting real-world complexities. Enter digital twins – a revolutionary approach to simulations that promises to usher in a new era of predictive power and optimization.

Beyond the Static Model: The Power of Real-Time Data

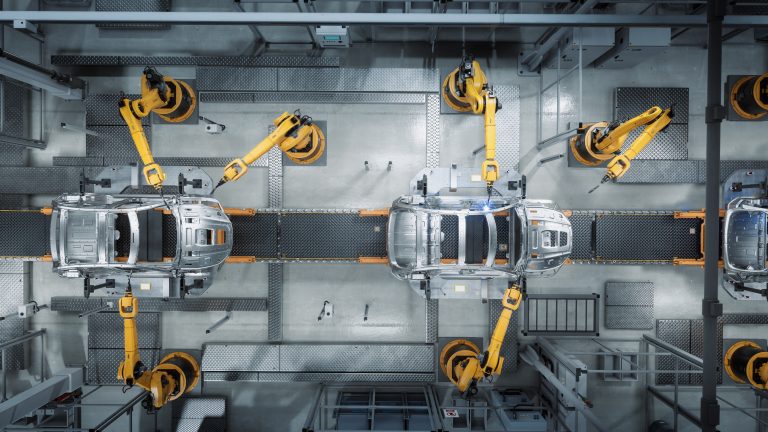

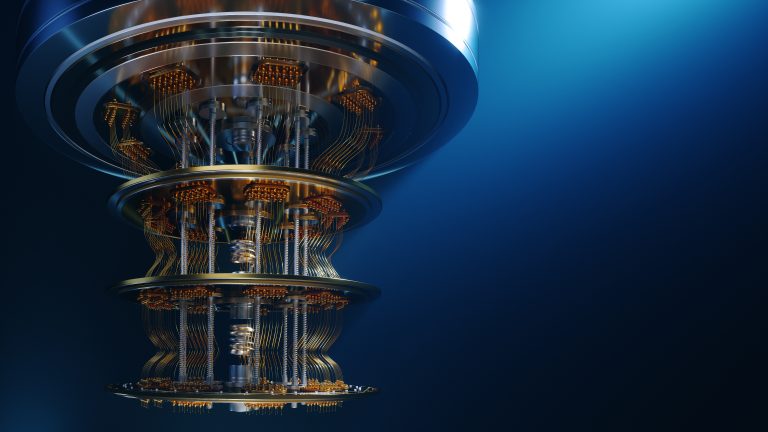

A digital twin is a virtual replica of a physical object, process, or system. What sets it apart from traditional simulations is its dynamic nature. Digital twins are constantly updated with real-time data from sensors embedded in their physical counterparts. This continuous flow of information allows the digital twin to evolve and adapt, reflecting the actual behavior of its physical counterpart much more accurately.

Imagine a digital twin of a jet engine. Traditional simulations might predict its performance under specific conditions. A digital twin, however, would incorporate real-time data on temperature, pressure, and wear and tear, providing a much more precise picture of the engine’s health and potential for failure.

Benefits of Digital Twins: A Glimpse into the Future

The potential benefits of digital twins are vast:

- Predictive Maintenance: By analyzing data from the digital twin, companies can predict equipment failures before they happen, allowing for preventive maintenance and avoiding costly downtime.

- Improved Design and Optimization: Engineers can use digital twins to test and optimize designs virtually, reducing the need for physical prototypes and accelerating innovation cycles.

- Enhanced Training and Education: Digital twins can be used to create immersive training simulations that mimic real-world scenarios, improving the effectiveness of training programs.

- Streamlined Decision-Making: Real-time insights from digital twins can inform better decision-making for operations, resource allocation, and overall business strategy.

Challenges and the Road Ahead: Building the Perfect Digital Twin

Despite their promise, digital twins face certain hurdles. Integrating sensors into physical systems can be complex and expensive. Additionally, managing and analyzing the vast amount of data generated by digital twins requires robust data management and analytics capabilities.

However, advancements in sensor technology, cloud computing, and big data analytics are rapidly addressing these challenges. As these technologies evolve, digital twins are poised to become even more powerful and ubiquitous.

The Future of Simulations: A Dynamic and Data-Driven Approach

Digital twins are not a complete replacement for traditional simulations. However, they represent a significant leap forward, offering a dynamic and data-driven approach to simulations. As the technology matures, we can expect digital twins to become the go-to tool for accurate simulations across various industries, shaping the future of prediction, optimization, and ultimately, success.